- Home

- >

- Composite Manufacturing

- >

- Robotized Acoustic Micro Drilling

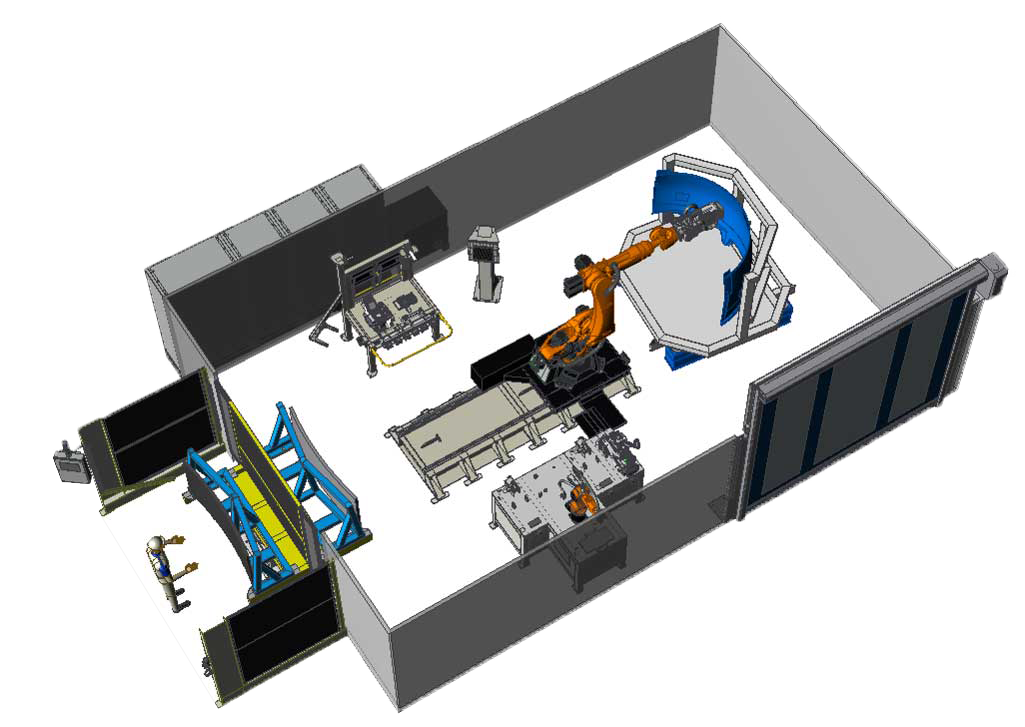

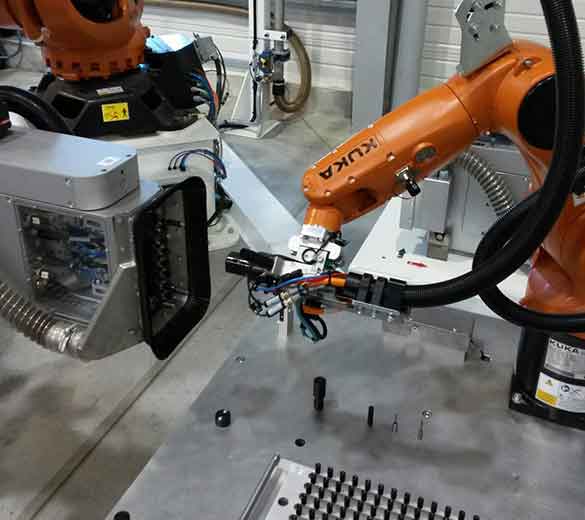

Drilling robot

Robotic Solution for Drilling Composites Acoustic Panels

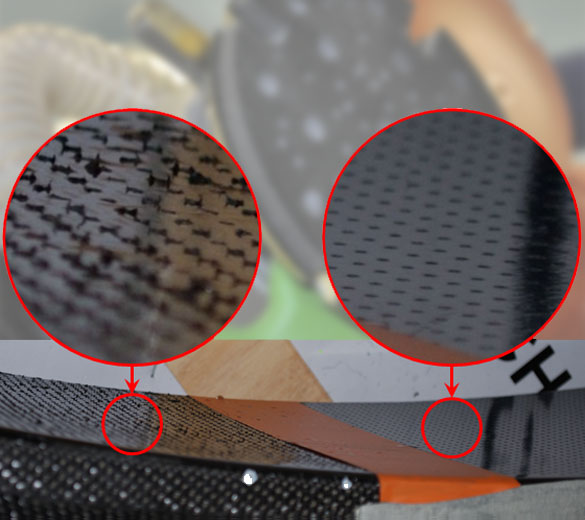

Manufacturing these panels is a real challenge partly because production rates have never been so high, and partly because of increasing pressure on production costs.

Our sister company GEBE2 designs and manufactures robotic cells with multi-spindle heads that provide greater flexibility than special machines, and are more cost-effective than solutions based on conventional CNC machine. This pioneering solution has been chosen to produce most of the acoustic panels for the LEAP.