- Home

- >

- Composite Manufacturing

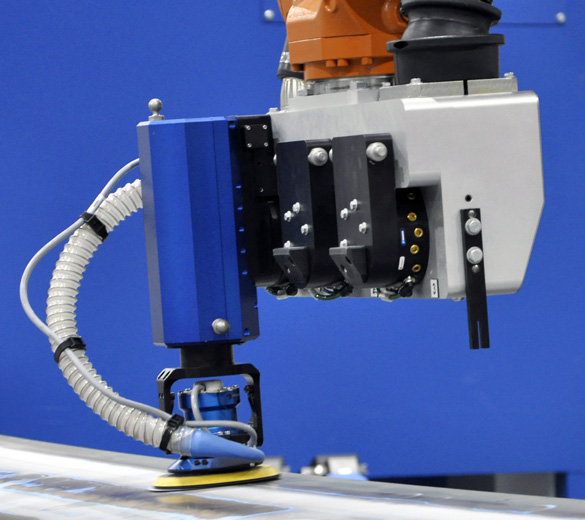

Robotic Platform and technical support

Test platform

In order to facilitate the roll-out of your industrial vision, our sister company GEBE2 has several robotic test cells equipped with demonstration equipment to conduct your feasibility and specific test programs.

Do you have a project? Do you want to develop a specific end effector? Please contact us!