- Home

- >

- Metal improvement

- >

- Ultrasonic Peen Forming

Portable Peen Forming Equipment

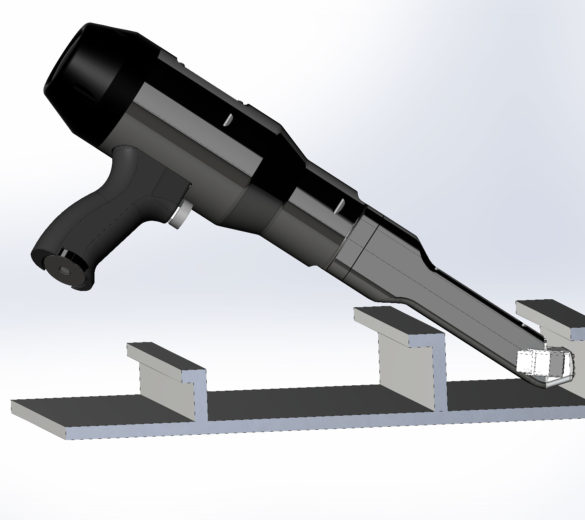

STRESSVOYAGER® UPF – Portable Ultrasonic Peen Forming equipment for aerospace

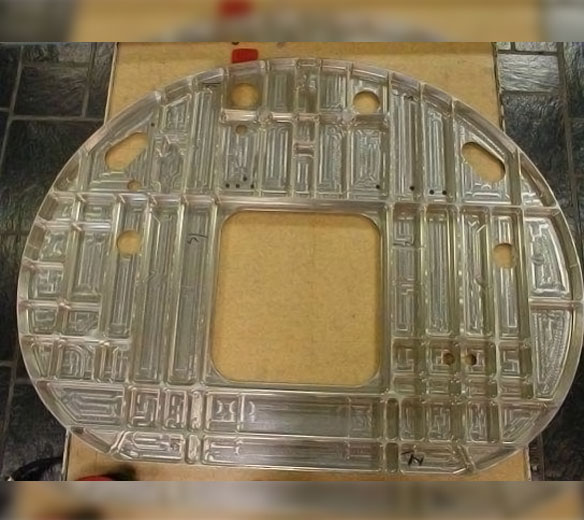

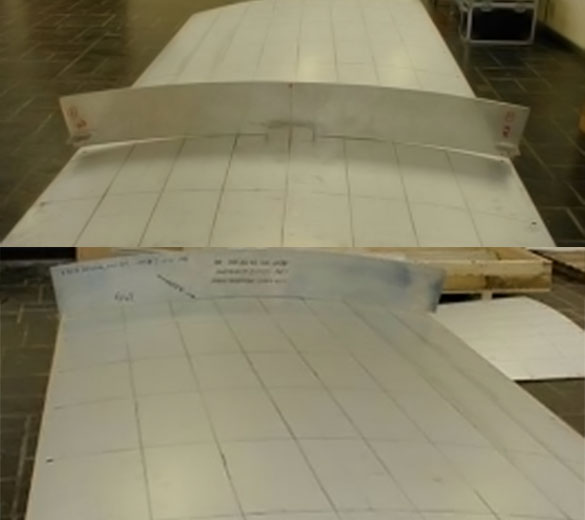

Our sister company SONATS has developed a portable, compact and lightweight equipment: the STRESSVOYAGER® UPF. This equipment is ideal for improving the productivity of your factories by allowing straightening or forming directly on the jig. This equipment is particularly used in the aerospace industry for forming wing and fuselage panels.

Moreover, thanks to the optimised design of the treatment head, its accessibility and its portability, the STRESSVOYAGER® UPF can be used to straighten complex geometry parts, with or without stiffeners, and of varying thickness (from 4 to 60mm).

The portable equipment allows to precisely adjust the shape of the metal parts during the controls-measurements which are particularly important for the aeronautical industry.