- Home

- >

- Metal improvement

- >

- Ultrasonic Peen Forming

Ultrasonic Peen Forming Process

Ultrasonic Peen Forming Process

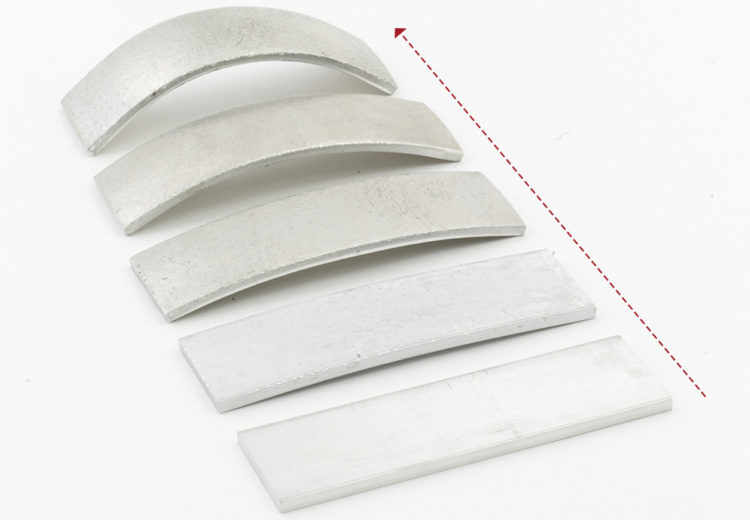

Mechanical Peen Forming operations , also called needle straightening or shot peen forming generally means finishing the shape of a component or a metal structure.

Following large deformations, these straightening or forming operations can be performed using a high-load press to exert mechanical pressure.

For finishing, or where deformation occurs after chemical or mechanical treatment, the most common way to precisely adjust the curvature of a work piece is to use a simple boilermaker hammer. The use of the hammer involves a significant treatment time and can cause musculoskeletal disorders to the operator. A pneumatic hammer may also be used.