- Home

- >

- Metal improvement

- >

- Ultrasonic Shot Peening

Ultrasonic Shot Peening Process

What is Ultrasonic Shot Peening ?

Our Ultrasonic Shot Peening (USP) process is used to improve:

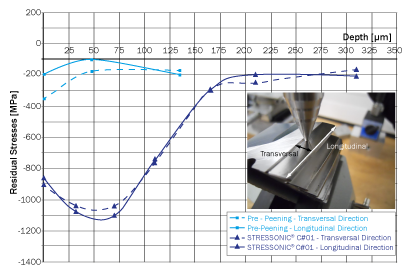

- Fatigue resistance

- Resistance to stress corrosion cracking and contact fatigue

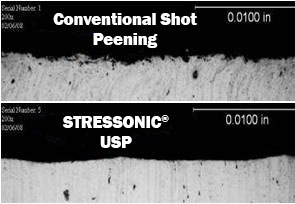

This surface impact treatment solution consists in bombarding the specific area to be peened with small projectiles (= media). This action induces residual compressive stress on the surface, which delays the appearance of cracks, and improves the lifetime of the part.