- Home

Automatic sanding

Automatic Sanding of Composite and Metal Materials

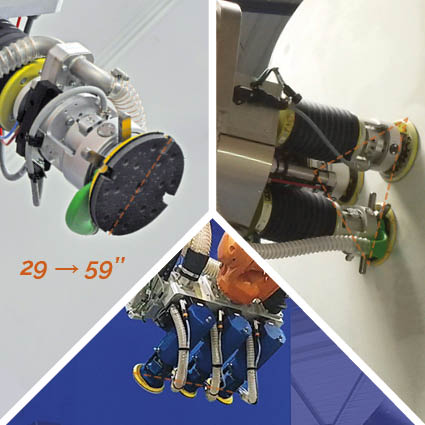

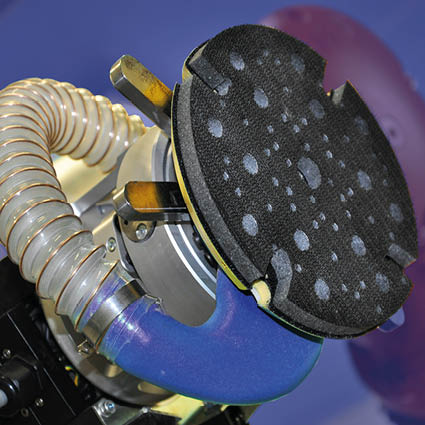

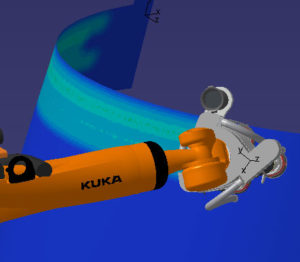

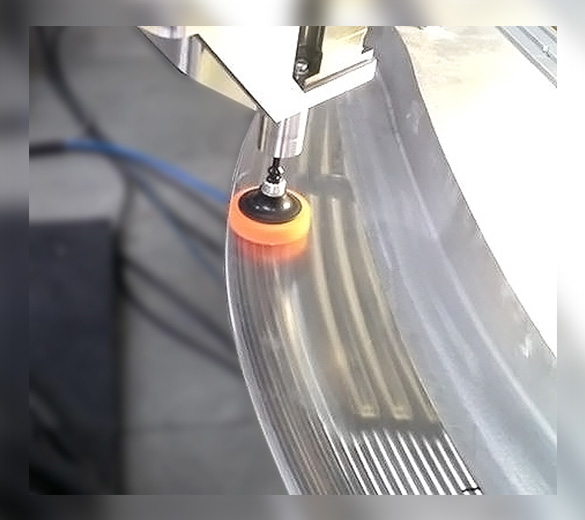

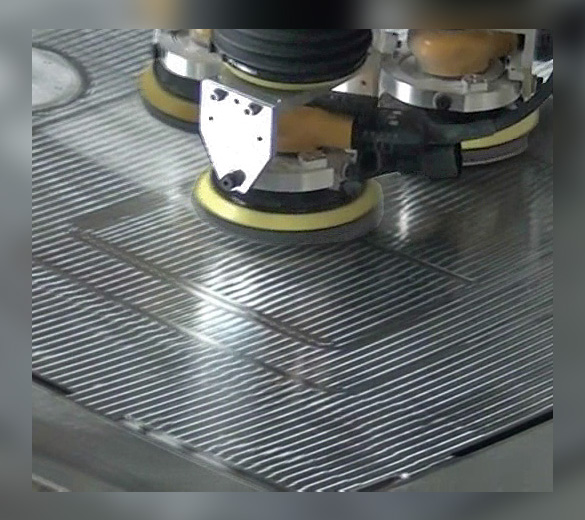

Our sister company GEBE2 has developed an automatic sanding solution that reproduces the operator’s gestures and sensitivity. The central element, the end-effector, is equipped with a random orbital electric sander and a compliant device that applies a constant force in all directions, down to the nearest N. This sanding robot enhances productivity and precision in industrial sanding applications.

To enhance the autonomy and performance of their robotic cells, GEBE2’s robot sander is equipped with an automatic disc changer that can handle a variety of grain sizes. This feature ensures that automatic sanding can continue without manual intervention, making it ideal for long production runs.

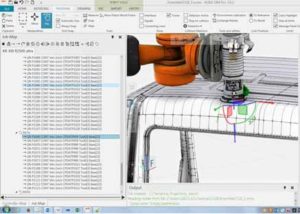

Sanding quality is strongly related to the regularity of the sander’s motion on the part. Our offline programming software simulates all possible trajectories with a graphical display of material removal, ensuring optimal results for both composite and metal parts.